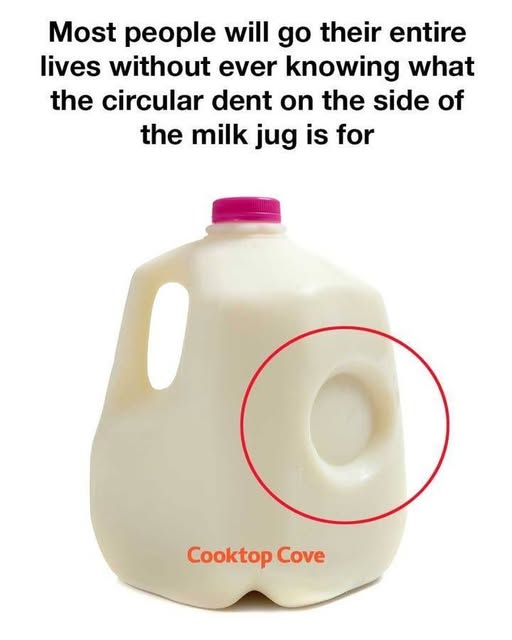

Common Misconceptions About the Circular Dent

Despite its importance, the circular dent is often misunderstood. Some people mistakenly believe that it is a flaw or defect in the jug, rather than an intentional design feature. Others may assume that it serves no purpose at all. These misconceptions highlight the gap between consumer perception and the reality of product design. By educating consumers about the true function of the dent, manufacturers can foster a greater appreciation for the engineering that goes into everyday items.

Conclusion: The Unseen Importance of a Simple Design Feature

The circular dent on the side of a milk jug is a testament to the ingenuity and thoughtfulness that goes into product design. While it may seem insignificant at first glance, this small feature plays a vital role in ensuring the safety, efficiency, and sustainability of milk packaging. By understanding the purpose and benefits of the dent, consumers can gain a deeper appreciation for the complexities of everyday objects and the unseen work that goes into making them both functional and reliable.

Additionally, the dent contributes to the structural integrity of the jug, preventing it from collapsing under pressure. By understanding these functions, consumers can appreciate the thought and engineering that goes into the design of a simple milk jug.

Historical Context: The Evolution of Milk Jug Design

The design of milk jugs has evolved significantly over the years. In the past, milk was delivered in glass bottles, which were heavy and prone to breaking. As the dairy industry grew, there was a need for a more durable and cost-effective solution. The introduction of plastic milk jugs in the mid-20th century revolutionized the industry, offering a lightweight and shatterproof alternative. The circular dent was introduced as part of this evolution, addressing the need for a design that could withstand the rigors of modern distribution and storage.

Reason 1: Structural Integrity and Pressure Management

ADVERTISEMENT